What is the role of MES management system in production management

What is the role of MES management system in production management

1. Fine management production

(1) The shift can judge whether there is wrong operation of the shift and the tank according to the inlet and outlet balance of the tank, so as to find out the problem and adjust it in time in case of imbalance.

(2) In the MES production management system, the movement amount is determined by the receipt and payment of the tank and its accuracy. The statisticians and dispatchers in the workshop can judge whether the data uploaded by the team is correct according to the difference to command, inspect the enterprise and supervise the material dynamics of the vehicle. If there is any problem, correct it in time.

(3) According to the input-output balance of each device, key users can check according to the profit and loss of the device. In case of abnormal profit and loss, they can find problems in time and provide corresponding help for production management.

(4) Relevant personnel balance the materials of the whole plant according to the tank level change curve of the product tank (treated as a buffer tank in the system) to achieve fine management.

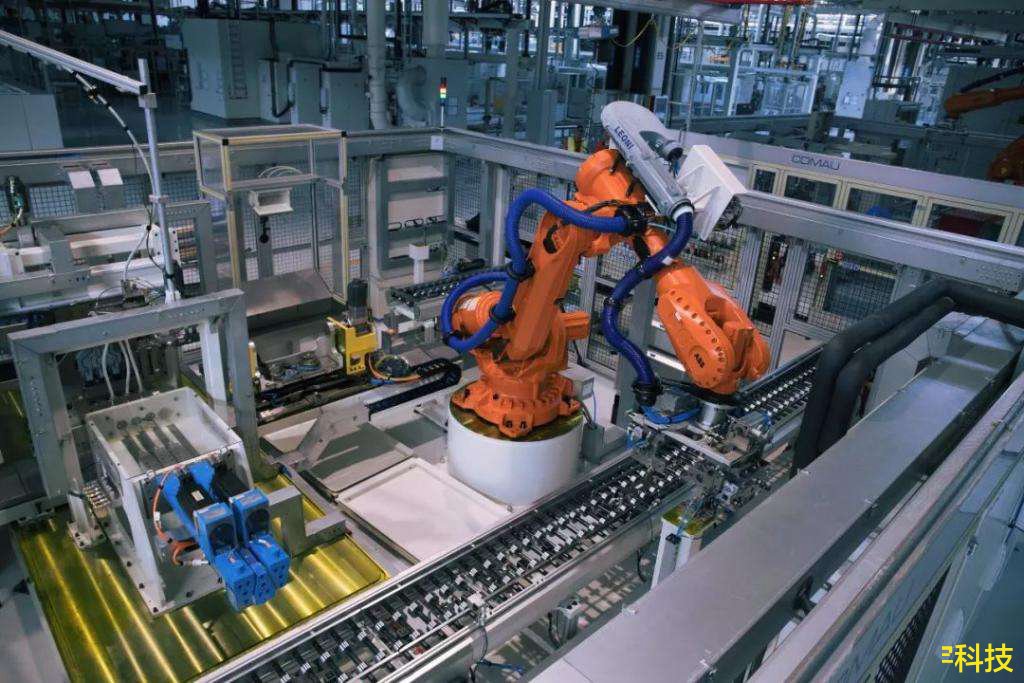

2. Realize the visual management of factory logistics

Provide a visual display platform to realize the factory logistics panorama.

Provide a variety of inspection tools, such as out of tolerance inspection, mobile relationship missing inspection, incoming and outgoing missing inspection and other inspection means. The system will automatically give a red alarm for the abnormal error so that the dispatcher can check and eliminate the difference in time.

explain: https://pics6.baidu.com/feed/622762d0f703918fa7d490c48bb9939d58eec4c2.jpeg?token=02a12eb2bf1213b5cfc40878793b1b83

MES management system

3. Realize the integration and sharing of production level data

The system provides an intuitive data display platform, so that dispatchers and production managers can consult relevant data they need to guide production according to their needs, breaking the traditional mode of directing production by telephone and making blind decisions. Decision managers can call out the data they want from the display platform at any time.

4. The enterprise benefit is improved

(1) Because the system provides an intuitive data display platform, the inventory of raw materials, products and semi-finished products in the workshop is intuitive and clear. The dispatcher can guide the production, control the inventory in a reasonable low inventory state, and save the inventory cost.

(2) The MES management system promotes the improvement of the enterprise informatization process. As an information execution system that supports ERP upward, relies on real-time data collection downward and DCS, the MES workshop management system plays a role of connecting the upper and lower parts in the whole information system chain, and builds a complete framework for the enterprise informatization and adapts to the informatization trend of the enterprise's future development.

(3) With the improvement of the enterprise's fine management, MES implements the management level by level, from the original department management to the workshop operator level management, making the management more refined.

(4) A leap in paperless office, from the original paper report to the current electronic report, from the original manual analysis to the current data integration, and from the original manual inspection to the current visual inspection, not only reduces the labor intensity of employees, but also makes problems transparent, so as to find problems and solve them in time

If you are looking for related products or have any other questions, you can call our sales hotline at any time

National unified hotline:86-755-28600211

01 留言咨询(设备、产量、价格、物料、流程等)

02 等待回访(30分钟内快速回复)

03 免费定制(根据需求免费量身定制流程方案)

想了解价格?产量?型号?售后?请留言,我们第一时间为您回复

在线留言

Online Service

Online Service