Advantages of machine vision inspection applied to industrial automation control

Advantages of machine vision inspection applied to industrial automation control

Machine vision is to measure and judge with machines instead of human eyes. It converts the target object into an image signal through an image pickup device and transmits it to an image processing system, which converts it into a digital signal according to information such as pixel distribution, brightness and color; The image system performs various operations on these signals to extract the characteristics of the target, and then acquires information according to the recognition results.

With the maturity of industrial automation technology and the maturity and development of machine vision technology, it has been more and more widely used in automatic production and manufacturing, and the industry development will also enter a new stage of rapid growth. The main reasons why machine vision plays an important role in industrial automation are as follows:

1. More efficient

The time that people can continue to work effectively is limited, and it is easy to fatigue and lack energy in the repeated mechanized detection process, so the detection efficiency is relatively low.

Machine vision can detect hundreds or even thousands of parts per minute. Especially when detecting high-speed moving targets, the machine can work continuously for 24 hours to improve the detection efficiency.

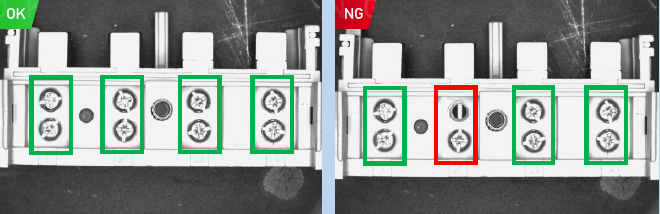

2. Higher accuracy

Human eyes are limited by physical conditions, that is, the use of magnifying glass or microscope to detect products will also be affected by subjectivity, physical strength and other factors, and the accuracy cannot be guaranteed. Different inspectors have different standards.

The machine is not subject to subjective control. As long as there is no difference in parameter settings, multiple machines with the same configuration can ensure the same accuracy.

3. Lower overall cost

Manual detection is a long-term and continuous cost investment. Traditional product testing belongs to the labor-intensive field. Now the labor and management costs are rising.

The input of machine vision inspection is mainly late, and one-time input ensures long-term output. In addition, machine detection is more effective than manual detection. In the long run, the cost of machine vision inspection is low.

4. Information integration

One person can only detect one content at a time. When manual detection is faced with different detection contents, it can only be completed through the coordination of multiple stations.

Machine vision inspection can measure multiple technical parameters at one time through multi station measurement method, such as the appearance, dimension, appearance defect and product height of the product to be inspected.

5. Digital statistics management

All measurement data generated by machine vision can be copied independently or through network connection to facilitate production process statistics and analysis. At the same time, the staff can export the specified measurement data and generate a report after the measurement, without manually adding one by one.

6. Can repeat continuous work for a long time

The machine can complete the testing work continuously for 24 hours without fatigue. Human energy is limited, and repeated testing for a long time will inevitably lead to fatigue. At this time, it is easy to make mistakes such as missed inspection, false inspection and false inspection, resulting in heavy losses.

7. It can be applied to hazard detection environment

The machine can be used in harsh and dangerous environments and in situations where human vision is difficult to meet the needs.

8. No contact damage

Machine vision does not need to contact the workpiece in the process of detecting the workpiece, nor does it cause contact damage to the workpiece. The workpiece must be manually inspected, which may easily cause contact damage.

9. More objective and stable

In the manual test process, the test results will be affected by personal standards, emotions, energy and other factors. The machine is carried out in strict accordance with the set standards, and the test results are more objective, reliable and stable.

10. Avoid man-made pollution

Some special production lines, such as pharmaceutical production sites, have extremely high hygiene requirements for the production and testing process. Machine vision inspection can avoid man-made pollution and ensure the cleanliness and quality of production inspection.This is the advantage of machine vision inspection in industrial automation. In addition, because the machine vision system can quickly acquire a large amount of information and automatically process it, and it is easy to combine with design information and processing control information, it is widely used in finished product inspection and quality control in modern automatic production process. At the same time, in the process of large-scale industrial production, when the efficiency of manual inspection of product quality is too low and the accuracy is not high, machine vision inspection can greatly improve industrial production efficiency and production automation, reduce rework, reduce recall, protect brand image, and improve enterprise competitiveness.

If you are looking for related products or have any other questions, you can call our sales hotline at any time

National unified hotline:86-755-28600211

01 留言咨询(设备、产量、价格、物料、流程等)

02 等待回访(30分钟内快速回复)

03 免费定制(根据需求免费量身定制流程方案)

想了解价格?产量?型号?售后?请留言,我们第一时间为您回复

在线留言

Online Service

Online Service